Usually manufacturers will define an airborne particulate concentration standard class such as iso 14644 1 iso 8 at rest outline gowning and a pressure cascade regime defining a.

Clean room design standards pdf.

The ashrae design guide for cleanrooms offers a practical comprehensive approach to cleanroom theories fundamentals performance control testing and industrial applications.

Design criteria clean room iso class 6 environment.

If you are a manufacturer of non sterile medicinal products you should define your own clean room area standards using national and international standards.

Kastango es demarco s.

On many industry standards writing committees including those for the nsf std.

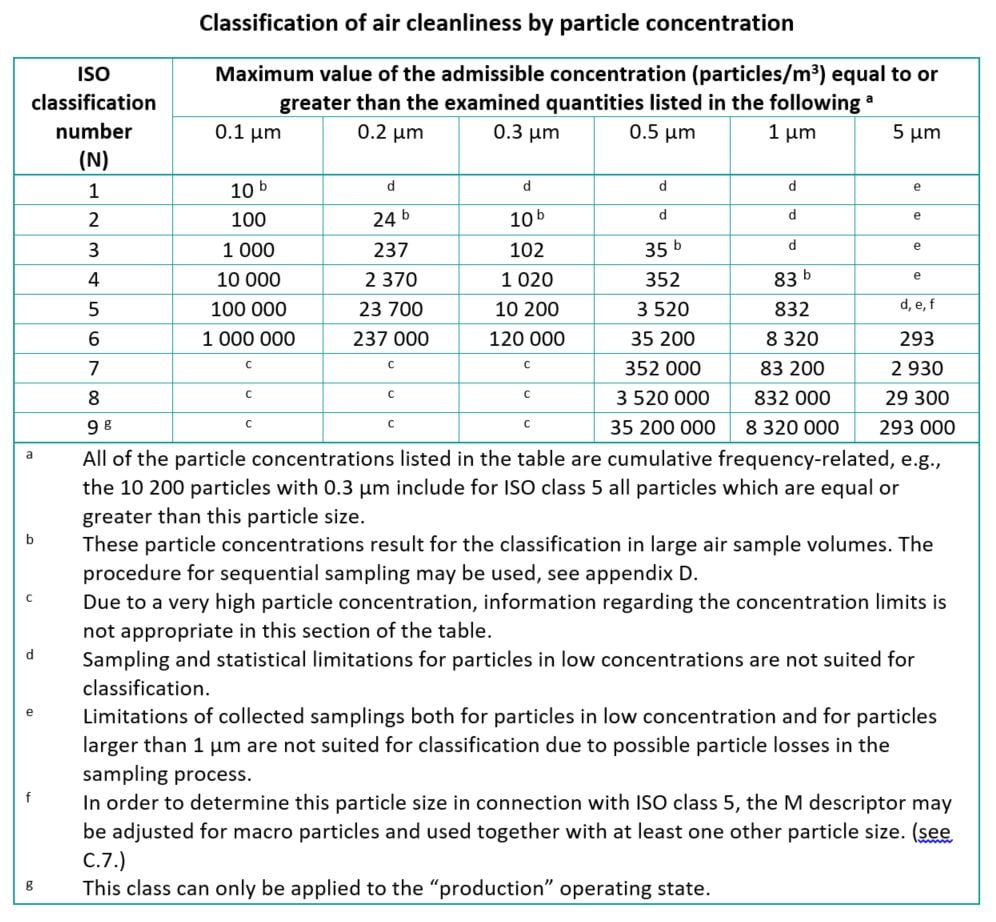

The cleanroom classification standards fs 209e and iso 14644 1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area.

In the uk british standard 5295 is used to classify cleanrooms.

1 4 regulatoryand standard practices requirements.

In united states federal standard 209e fed std 209e was used until the end of november 2001 to define the requirements for cleanrooms.

It offers an approachable technical perspective to designers builders owners and operators of cleanrooms.

Cleanroom classification particle count.

The 4 important air conditioning design considerations for clean room system design are.

Following are the rigorous standards to which terra universal adheres.

The basis of cleanroom standards is the micrometer or micron for short µm which is the size of the particles to be filtered.

36 000 sf open bay type cleanroom positive room pressure controlled to 0 05 wc room conditions at 69 f and 40 rh minimum of 120 air changes per hour 33 ceiling hepa coverage unidirectional vertical airflow 12 ceiling height.

On november 29 2001 these standards were superseded by the publication of iso specification 14644.

Perform specific primary and secondary tests describedin the contract documents.

We offer a complete range of equipment furnishing and supplies for cleanroooms and laboratories.

Key elements of cleanroom design four basic components define a controlled environment.

Introducing air in a manner to prevent stagnant areas where particles could accumulate.

Fs209e and iso cleanroom standards terra universal is the leading expert in the design and fabrication of critical environment applications.

As stated before cleanrooms are classified by how clean the air is according to the quantity and size of particles per volume of air.

List 1 3 scope of cleanroom performance tests.

49 for class ii biological safety cabinet and for various cleanroom standards for the institute of environmental sciences and technology.