Sheet metal clinching styles clinching point shapes tox pressotechnik.

Clinch lock sheet metal.

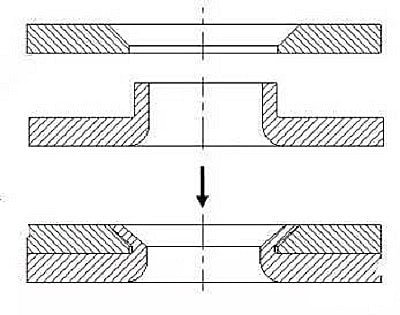

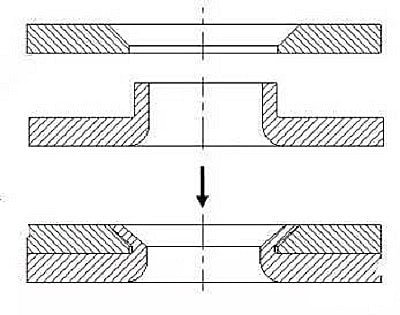

With the clinching process sheet metals of different thicknesses or other materials even with adhesives or other intermediate layers are joined in a cold forming process.

Steel press fit nuts for sheet metal also known as clinch style captive nuts press these nuts into a drilled or punched hole with an arbor press or similar pressure tool.

Clinching or press joining is a bulk sheet metal forming process aimed at joining thin metal sheet without additional components using special tools to plastically form an interlock between two or more sheets.

The basics of clinching also known as press joining clinching refers to the use of a punch and die set to press or clinch two or more pieces of sheet metal together.

Find the right clinching joint for your sheet metal joining application.

Clinching provides a cleaner alternative to riveting and spot welding.

Architectural college universities hvac sheetmetal job shop portable roofing.

In industrial applications clinching is being applied for single sheet thicknesses of 0 1 mm up to a total layer thickness of 12 mm 47 and up to 800 n mm 2 5 7 lbf in2.

This clinching machine is easy to handle and use.

Captive self clinching fasteners are designed to be installed in sheet metal and pc boards.

Lightweight for great portability.

Typical strengths in pounds for stainless steel.

The ez clinch is simple light and easy.

They provide a permanently attached threaded fastener which becomes an integral part of the panel or frame and eliminates the challenges associated with loose hardware.

Description specifications brochures get a quote description.

Clinching stainless steel typically requires the use of a rectangular clinching type that is often referred to as lance clinching.

While the sheet metal may be preheated the process is typically performed at room temperature.

The tox clinch procedure is a proven substitute for welding screwing riveting.

Clinch systems by juradotools based in italy offers products and solutions for cost effective assembly of sheet metal products to a large variety of industrial sectors worldwide such as automobile appliance refrigeration building electric furniture and many others sectors.

The interlocking feature forms water tight permanent joints between them.